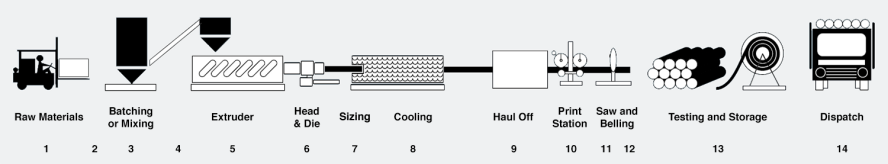

Yeej, PVC cov khoom yog tsim los ntawm raw PVC hmoov los yog cov tebchaw los ntawm cov txheej txheem ntawm tshav kub thiab siab.Ob txheej txheem loj siv hauv kev tsim khoom yog extrusion molding.

Cov txheej txheem PVC niaj hnub no suav nrog cov txheej txheem kev tshawb fawb uas xav tau kev tswj xyuas meej ntawm cov txheej txheem sib txawv.Cov khoom siv polymer yog cov hmoov ntws dawb, uas yuav tsum tau ntxiv cov stabilizers thiab kev pab ua haujlwm.Formulation thiab blending yog cov theem tseem ceeb ntawm cov txheej txheem thiab nruj specifications yog khaws cia rau cov khoom raw khoom, batching thiab sib tov.Pub rau lub extrusion los yog molding tshuab yuav ncaj qha, nyob rau hauv daim ntawv ntawm "qhuav blend", los yog pre-processed rau hauv ib tug granular "compound".

Extrusion

Polymer thiab additives (1) raug ntsuas kom raug (2) thiab ua tiav los ntawm kev sib xyaw ua haujlwm siab (3) txhawm rau muab cov khoom siv raw rau hauv cov khoom sib xyaw qhuav qhuav sib xyaw.Qhov sib tov kub ntawm ib ncig ntawm 120 ° C yog ua tiav los ntawm kev sib txhuam kub.Nyob rau hauv ntau theem ntawm kev sib tov, cov additives yaj thiab zuj zus txheej txheej PVC polymer granules.Tom qab ncav cuag qhov ntsuas kub uas yuav tsum tau ua, cov khoom sib xyaw tau txiav tawm mus rau hauv chav txias txias uas txo qhov kub ntawm ib ncig 50 ° C, yog li tso cai rau cov khoom sib xyaw kom xa mus rau nruab nrab cia (4) qhov twg txawm tias qhov kub thiab qhov sib xws tau ua tiav.

Lub plawv ntawm tus txheej txheem, lub extruder (5), muaj ib tug kub-tswj, zoned chim nyob rau hauv uas tig precision "screws".Niaj hnub nimno extruder screws yog cov khoom siv nyuaj, ua tib zoo tsim nrog kev sib txawv ntawm cov davhlau los tswj cov compression thiab shear, tsim nyob rau hauv cov khoom, thaum lub sij hawm tag nrho cov txheej txheem.Lub ntxaib counter-rotating ntsia hlau configuration siv los ntawm tag nrho cov loj manufacturers muab kev txhim kho ua.

Lub PVC dryblen yog ntsuas rau hauv lub thoob thiab cov ntsia hlau, uas tom qab ntawd hloov cov hmoov qhuav rau hauv lub xeev "melt" xav tau, los ntawm tshav kub, siab thiab shear.Thaum nws txoj kev hla cov ntsia hlau, PVC hla dhau ntau thaj chaw uas compress, homogenise thiab vent lub yaj kwj.Qhov kawg cheeb tsam nce siab kom extrude lub yaj los ntawm lub taub hau thiab tuag teeb (6) uas yog zoo li tus raws li qhov loj ntawm cov yeeb nkab yuav tsum tau thiab ntws yam ntxwv ntawm cov yaj kwj.Thaum cov yeeb nkab tawm ntawm extrusion tuag, nws yog qhov loj los ntawm kev hla lub tes tsho precision nrog lub tshuab nqus tsev sab nraud.Qhov no yog qhov txaus los ua kom cov txheej txheem sab nrauv ntawm PVC thiab tuav cov yeeb nkab txoj kab uas hla thaum lub caij txias kawg hauv chav dej txias (8).

Cov yeeb nkab yog rub los ntawm qhov loj me thiab kev ua haujlwm txias los ntawm kev rub tawm lossis rub tawm (9) ntawm qhov ceev tsis tu ncua.Kev tswj ceev yog qhov tseem ceeb heev thaum siv cov cuab yeej no vim tias qhov ceev ntawm cov yeeb nkab rub yuav cuam tshuam rau phab ntsa thickness ntawm cov khoom tiav.Nyob rau hauv cov ntaub ntawv ntawm cov roj hmab nplhaib sib txuas cov yeeb nkab lub haul-off yog qeeb qeeb ntawm lub sijhawm tsim nyog kom thicken cov yeeb nkab hauv cheeb tsam ntawm lub qhov (socket).

Lub tshuab luam ntawv hauv-kab (10) cim cov kav dej ntawm lub sijhawm tsis tu ncua, nrog rau kev txheeb xyuas raws li qhov loj me, chav kawm, hom, hnub tim, Tus Qauv Zauv, thiab tus lej extruder.Lub tshuab txiav txiav tsis siv neeg (11) txiav cov yeeb nkab rau qhov ntev uas yuav tsum tau ua.

Lub tshuab belling tsim ib lub qhov (socket) ntawm qhov kawg ntawm txhua qhov ntev ntawm cov yeeb nkab (12).Muaj ob hom ntawm lub qhov (socket).Rau cov roj hmab-ntiv nplhaib sib txuas cov yeeb nkab, ib lub mandrel collapsible yog siv, whereas ib tug dawb mandrel yog siv rau hnyav sib koom ua ke sockets.Roj hmab nplhaib yeeb nkab yuav tsum tau ib tug chamfer ntawm lub spigot, uas yog tua nyob rau hauv lub saw chaw nres tsheb los yog belling unit.

Cov khoom tiav yog muab khaws cia rau hauv qhov chaw rau kev tshuaj xyuas thiab kev kuaj zaum kawg thiab kev lees paub zoo (13).Txhua qhov kev tsim khoom raug kuaj thiab tshuaj xyuas raws li qhov tsim nyog Australian Standard thiab / lossis cov lus qhia tshwj xeeb ntawm tus neeg yuav khoom.

Tom qab kuaj xyuas thiab lees txais, cov yeeb nkab tau muab khaws cia kom tos qhov kawg xa tawm (14).

Rau kev taw qhia PVC (PVC-O) cov kav dej, cov txheej txheem extrusion yog ua raws li cov txheej txheem nthuav dav ntxiv uas yuav siv qhov chaw raws li tau hais tseg thiab ua tib zoo tswj xyuas qhov kub thiab txias.Nws yog thaum lub sij hawm nthuav dav uas lub molecular orientation, uas imparts lub siab lub zog ntawm PVC-O, tshwm sim.

Post lub sij hawm: Dec-21-2022