Yas extrusion yog nyob rau hauv nquag siv nyob rau hauv niaj hnub kev lag luam plastics vim nws yog yooj yim thiab yooj yim mus ua hauj lwm nrog.Cov txheej txheem yas extrusion muaj cov khoom siv yas yaj, yuam nws mus rau hauv qhov tuag los ua kom nws mus rau hauv qhov profile txuas ntxiv, thiab tom qab ntawd txiav nws kom ntev.Cov txheej txheem yog ib qho kev xaiv zoo rau cov ntawv thov uas xav tau cov khoom kawg nrog rau qhov ntu ntu tas li.Tus nqi qis thiab tus nqi ntau lawm ua rau nws yog ib qho kev xaiv tsim khoom rau cov khoom xws li cov kav dej, cov ntawv yas, cov huab cua stripping, rwb thaiv tsev hlau thiab cov nplaum nplaum.

Cov khoom siv yas Extrusion

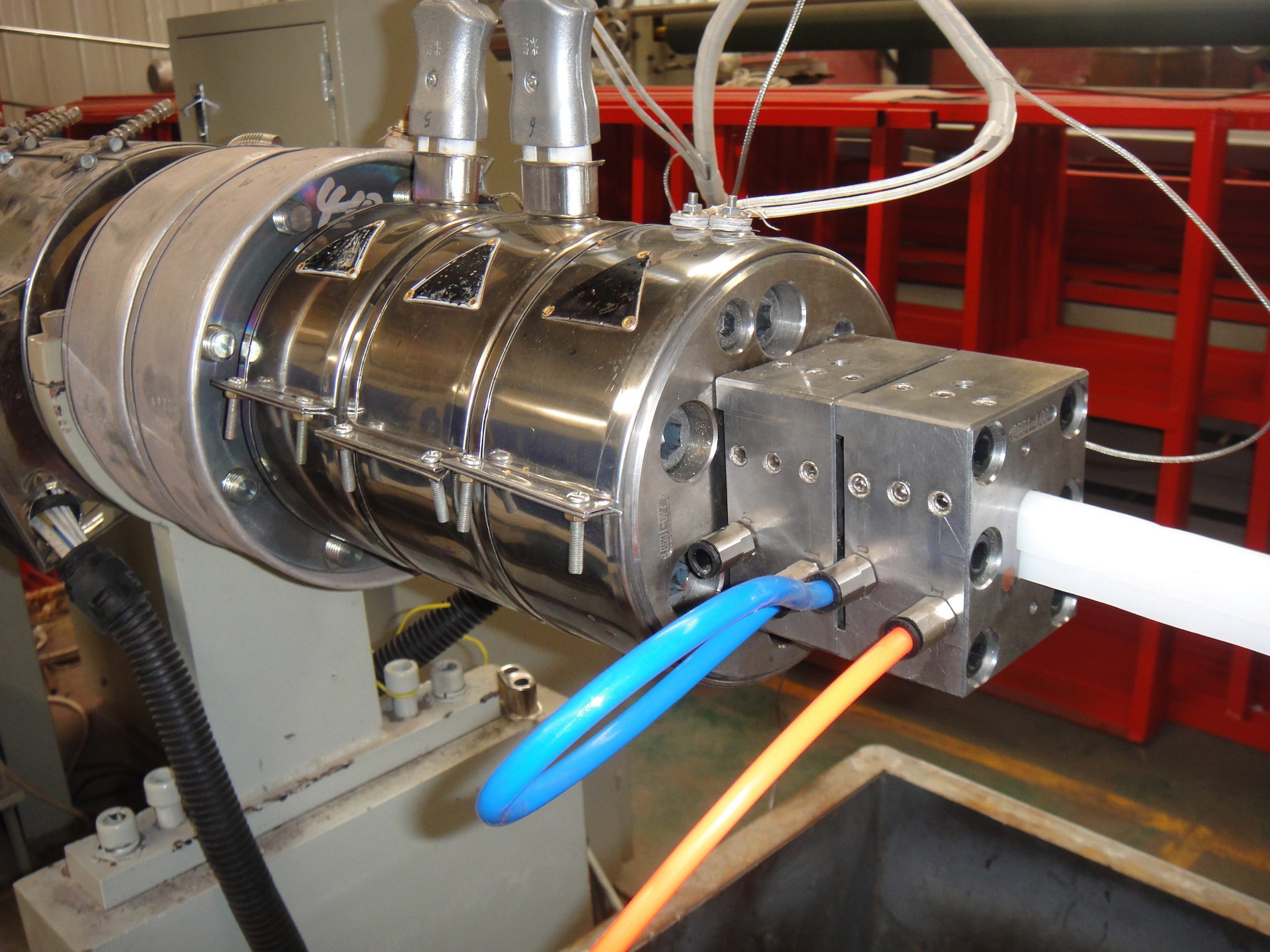

Ua ntej pib cov txheej txheem yas extrusion, cov tshuab tsim nyog thiab cov khoom siv yuav tsum tau txais, tshwj xeeb yog lub tshuab yas extruder.Cov cuab yeej no yog lub tshuab yooj yim yooj yim uas pab txhawb cov txheej txheem extrusion txij thaum pib mus rau qhov kawg.Cov khoom tseem ceeb ntawm cov yas extruder muaj xws li hopper, chim, ntsia hlau tsav thiab ntsia hlau tsav lub cev muaj zog.

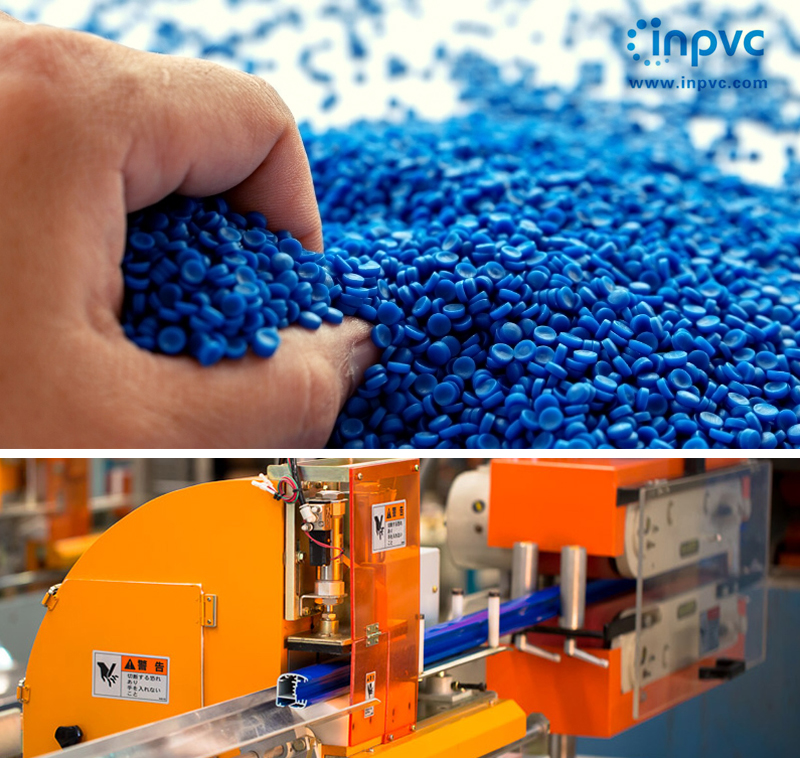

Qhov thib ob tseem ceeb tshaj plaws yog cov khoom siv thermoplastic raw khoom rau extrusion.Feem ntau ntawm kev ua haujlwm extrusion cia siab rau cov yas yas (cov hlaws me me) kom tso cai rau kev thauj khoom yooj yim thiab lub sijhawm melting ceev.Cov ntaub ntawv yas uas siv hauv cov txheej txheem extrusion muaj xws li kev cuam tshuam siab polystyrene (HIPS), PVC, polyethylene, polypropylene, thiab ABS.

Qhov kawg tivthaiv tsim nyog rau yas extrusion yog tuag.Cov tuag ua haujlwm ua pwm rau cov yas-hauv cov yas extrusion, tuag cia rau txawm tias cov yas molten.Kev tuag feem ntau yuav tsum tau ua raws li kev cai thiab tej zaum yuav xav tau lub sijhawm ua ntej ua ntej pib txheej txheem tsim khoom.

Cov txheej txheem tshwj xeeb yas Extrusion

Ntau daim ntawv thov hu rau cov txheej txheem extrusion tshwj xeeb kom tau txais txiaj ntsig zoo lossis ua kom cov txheej txheem ntau lawm.Cov txheej txheem tshwj xeeb extrusion feem ntau suav nrog:

●Blown zaj duab xis extrusion:Siv los tsim cov khoom yas yas xws li khoom noj khoom haus thiab cov hnab ntim khoom noj Cov tuag nyob rau hauv cov txheej txheem no feature ib tug upright, cylindrical tsim uas rub lub molten yas upward raws li nws cov ntaub ntawv thiab txias.

●Co-extrusion:Ob peb txheej yog extruded tib lub sijhawm.Ob los yog ntau tshaj extruders pub ntau hom yas rau hauv ib lub taub hau extrusion.

●Hla lub tsho:Extrusion yog ua hauj lwm los coated ib yam khoom nyob rau hauv kev tiv thaiv yas txheej.Sab nrauv hlau thiab cable jacketing yog feem ntau daim ntawv thov ntawm overjacketing.

●Tubing extrusion:Zoo ib yam li cov tsoos extrusion, tshwj tsis yog cov tuag suav nrog cov pins sab hauv lossis mandrels los pab tsim cov khoom siv yas hollow.

Cov txheej txheem yooj yim ntawm Yas Extrusion

Cov txheej txheem yas extrusion pib nrog kev tso cov khoom nyoos rau hauv lub extruder lub hopper.Yog tias cov resin tsis muaj cov tshuaj ntxiv uas tsim nyog rau daim ntawv thov tshwj xeeb (xws li UV inhibitors, anti-oxidants, lossis colorants), ces lawv ntxiv rau lub hopper.Ib zaug nyob rau hauv qhov chaw, cov resin feem ntau yog nqus los ntawm lub caj pas pub ntawm lub hopper mus rau hauv lub extruder lub chim.Nyob rau hauv lub chim yog ib tug ntev, rotating ntsia hlau uas pub cov resin rau pem hauv ntej chim rau cov tuag.

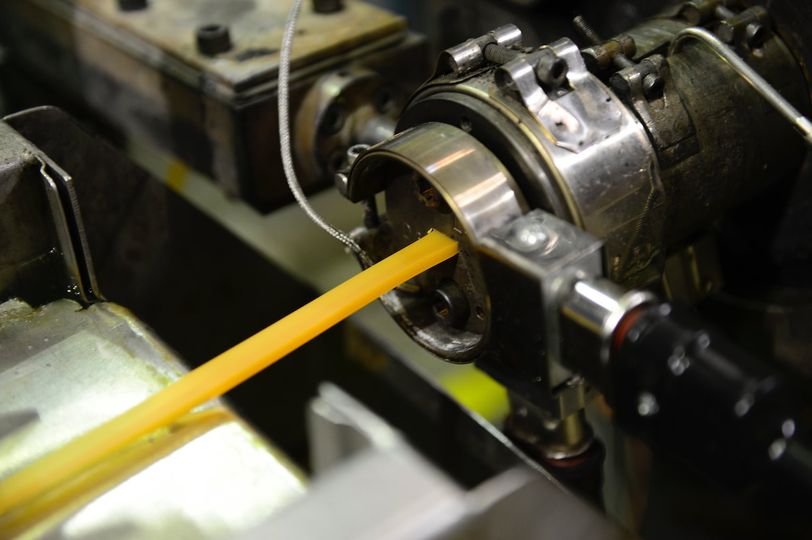

Raws li cov resin txav mus rau hauv lub thoob, nws raug kub siab heev kom txog thaum nws pib yaj.Nyob ntawm seb hom thermoplastic, qhov kub thiab txias tuaj yeem nyob nruab nrab ntawm 400 thiab 530 degrees Fahrenheit.Feem ntau cov extruder muaj lub thoob uas maj mam nce hauv tshav kub los ntawm kev thauj khoom kawg mus rau cov yeeb nkab pub kom maj mam yaj thiab txo qhov muaj peev xwm ntawm cov yas degradation.

Thaum cov yas molten mus txog qhov kawg ntawm lub thoob, nws raug yuam los ntawm ib lub npov pob thiab muab tso rau hauv cov yeeb nkab pub uas ua rau tuag.Lub vijtsam, txhawb nqa los ntawm lub phaj tawg vim muaj kev kub ntxhov hauv lub thoob, pab tshem tawm cov kab mob uas muaj nyob hauv cov yas molten.Lub porosity ntawm lub vijtsam, tus naj npawb ntawm cov ntxaij vab tshaus, thiab lwm yam tuaj yeem hloov kho kom txog thaum cov txheej txheem melting tshwm sim los ntawm qhov zoo ntawm lub zog rov qab.

Ib zaug nyob rau hauv cov yeeb nkab pub, cov hlau molten yog pub rau hauv qhov tuag kab noj hniav, qhov twg nws txias thiab hardens.Txhawm rau kom ceev cov txheej txheem ua kom txias, cov yas tsim tshiab tau txais ib lub da dej kaw.Nyob rau hauv cov ntaub ntawv ntawm yas sheeting extrusion, txias yob hloov cov dej da dej.

Post lub sij hawm: Oct-25-2021